How does glass fiber improve the safety of electrical equipment through its high dielectric strength?

Release Time : 2025-04-21

In the field of modern electronics and electrical engineering, choosing the right insulating material is one of the key factors to ensure the safe operation of equipment. As a high-performance insulating material widely used in various electrical equipment, glass fiber plays an important role in improving the safety of equipment with its excellent physical and electrical properties. In particular, its high dielectric strength provides a reliable protective barrier for electrical equipment, avoiding short circuits and other potential dangers.

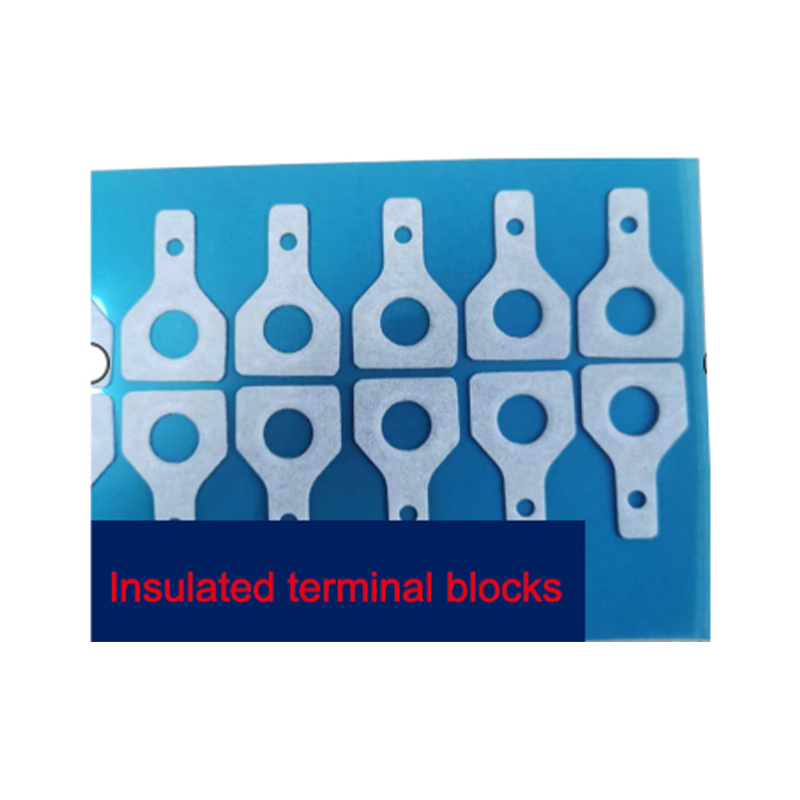

First of all, it is important to understand what dielectric strength is. Dielectric strength refers to the maximum electric field strength that a material can withstand. When this strength is exceeded, the material will undergo electrical breakdown, that is, the current will penetrate the insulator and cause a short circuit or damage. Glass fiber is known for its excellent dielectric strength, which is mainly due to its unique material composition. It is made of epoxy resin and glass fiber fabric layers, and this combination gives the material extremely high electrical insulation properties. Even under high voltage environments, glass fiber can effectively prevent current leakage, thereby protecting internal electronic components from damage.

Secondly, the high dielectric strength of glass fiber makes it an ideal choice for making printed circuit boards (PCBs). In high-frequency circuit boards, signal transmission speed is very fast, and any slight change in capacitance may cause signal distortion or interference. Because glass fiber has excellent dielectric constant stability, it can maintain consistent electrical properties over a wide range of operating frequencies, ensuring the purity and reliability of signal transmission. In addition, its low loss factor also means that energy loss is minimized under high-frequency operation, improving the efficiency of the overall system.

Furthermore, glass fiber not only performs well in electrical performance, but also has significant advantages in mechanical performance. Its high strength and rigidity enable it to withstand large mechanical stress, which is particularly important for electrical equipment that needs to be used in harsh working environments. For example, in industrial automation equipment, glass fiber not only provides the necessary electrical isolation, but also resists vibration and shock, ensuring long-term stable operation of the equipment. This double guarantee greatly enhances the overall safety of the equipment.

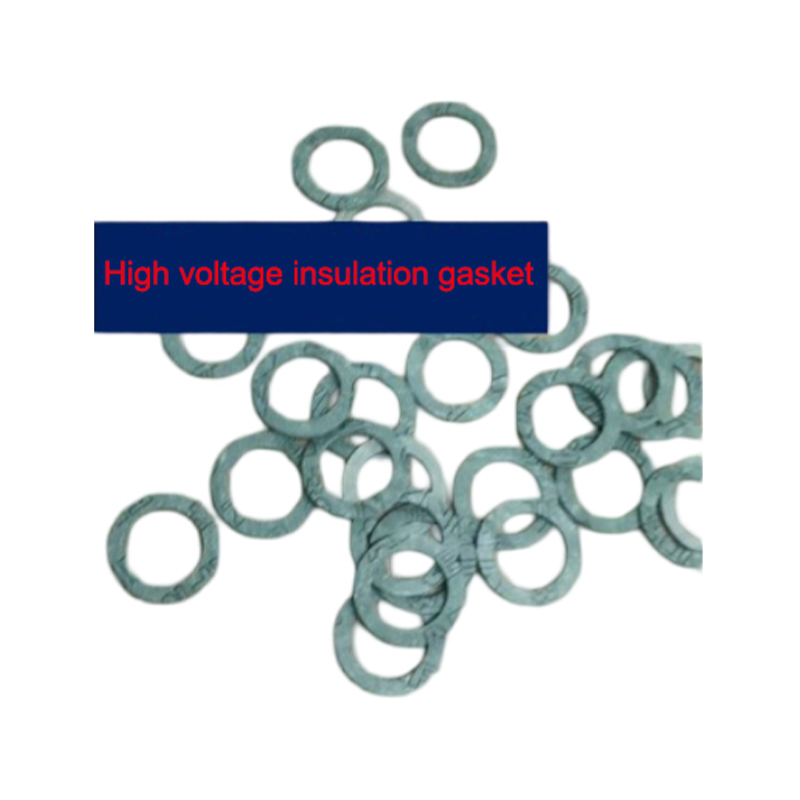

It is worth mentioning that the high dielectric strength of glass fiber is also reflected in its arc resistance. When electrical equipment fails, arc discharge may occur, which is an extremely dangerous phenomenon that may cause fire or even explosion. However, due to its high dielectric strength and good flame retardant properties, glass fiber can effectively inhibit the formation and development of arcs, thereby reducing the risk of accidents and protecting the safety of personnel and property.

In addition, glass fiber uses strict production process control during the manufacturing process to ensure the close bonding between each layer of materials, eliminate possible bubbles or defects, and further improve its dielectric strength. This fine manufacturing process not only improves the quality of the product, but also extends its service life and reduces the cost of repair and replacement due to material failure.

Finally, with the increasing awareness of environmental protection, glass fiber manufacturers have also begun to pay attention to the sustainable development of materials. Many new FR4 materials use more environmentally friendly resin systems, reduce the use of harmful substances, while maintaining the original excellent electrical properties. This green transformation not only meets the requirements of current environmental regulations, but also provides users with a safer and healthier use experience.

In short, glass fiber has demonstrated irreplaceable value in improving the safety of electrical equipment through its high dielectric strength. Whether it is used for household appliances, industrial control systems or high-tech electronic products, glass fiber can provide strong electrical isolation protection to ensure the efficient operation and long-term durability of the equipment. In the future, with the continuous emergence of new materials and new technologies, we have reason to believe that glass fiber will show its unique advantages in more fields and continue to promote the development and technological progress of related industries.

First of all, it is important to understand what dielectric strength is. Dielectric strength refers to the maximum electric field strength that a material can withstand. When this strength is exceeded, the material will undergo electrical breakdown, that is, the current will penetrate the insulator and cause a short circuit or damage. Glass fiber is known for its excellent dielectric strength, which is mainly due to its unique material composition. It is made of epoxy resin and glass fiber fabric layers, and this combination gives the material extremely high electrical insulation properties. Even under high voltage environments, glass fiber can effectively prevent current leakage, thereby protecting internal electronic components from damage.

Secondly, the high dielectric strength of glass fiber makes it an ideal choice for making printed circuit boards (PCBs). In high-frequency circuit boards, signal transmission speed is very fast, and any slight change in capacitance may cause signal distortion or interference. Because glass fiber has excellent dielectric constant stability, it can maintain consistent electrical properties over a wide range of operating frequencies, ensuring the purity and reliability of signal transmission. In addition, its low loss factor also means that energy loss is minimized under high-frequency operation, improving the efficiency of the overall system.

Furthermore, glass fiber not only performs well in electrical performance, but also has significant advantages in mechanical performance. Its high strength and rigidity enable it to withstand large mechanical stress, which is particularly important for electrical equipment that needs to be used in harsh working environments. For example, in industrial automation equipment, glass fiber not only provides the necessary electrical isolation, but also resists vibration and shock, ensuring long-term stable operation of the equipment. This double guarantee greatly enhances the overall safety of the equipment.

It is worth mentioning that the high dielectric strength of glass fiber is also reflected in its arc resistance. When electrical equipment fails, arc discharge may occur, which is an extremely dangerous phenomenon that may cause fire or even explosion. However, due to its high dielectric strength and good flame retardant properties, glass fiber can effectively inhibit the formation and development of arcs, thereby reducing the risk of accidents and protecting the safety of personnel and property.

In addition, glass fiber uses strict production process control during the manufacturing process to ensure the close bonding between each layer of materials, eliminate possible bubbles or defects, and further improve its dielectric strength. This fine manufacturing process not only improves the quality of the product, but also extends its service life and reduces the cost of repair and replacement due to material failure.

Finally, with the increasing awareness of environmental protection, glass fiber manufacturers have also begun to pay attention to the sustainable development of materials. Many new FR4 materials use more environmentally friendly resin systems, reduce the use of harmful substances, while maintaining the original excellent electrical properties. This green transformation not only meets the requirements of current environmental regulations, but also provides users with a safer and healthier use experience.

In short, glass fiber has demonstrated irreplaceable value in improving the safety of electrical equipment through its high dielectric strength. Whether it is used for household appliances, industrial control systems or high-tech electronic products, glass fiber can provide strong electrical isolation protection to ensure the efficient operation and long-term durability of the equipment. In the future, with the continuous emergence of new materials and new technologies, we have reason to believe that glass fiber will show its unique advantages in more fields and continue to promote the development and technological progress of related industries.