How does slow rebound EPDM foam improve the shock protection of electronic devices?

Release Time : 2025-03-13

Slow rebound EPDM foam plays an important role in improving the shock protection of electronic devices. This material has been widely used in the field of electronic equipment packaging and protection due to its unique properties.

1. Material properties

Weather resistance and aging resistance: EPDM itself has excellent weather resistance and aging resistance, which means that it can be used for a long time in various harsh environmental conditions without easy degradation. This performance is crucial for electronic devices, because electronic devices usually need to operate in various environments, including high temperature, low temperature, humidity, etc.

High and low temperature resistance: EPDM can be used in the range of -40~+120℃ and has the characteristics of high and low temperature resistance. The stability within this temperature range ensures that electronic devices can be well protected under different temperature conditions.

Slow rebound and cushioning: Slow rebound EPDM foam has excellent slow rebound elasticity and can quickly recover its shape when impacted. This cushioning property can effectively absorb and disperse the impact force, thereby protecting electronic devices from damage.

2. Shockproof protection mechanism

Impact absorption: When an electronic device is impacted, Slow Rebound EPDM foam can quickly absorb the impact force and disperse it throughout the material structure. This impact absorption mechanism significantly reduces the risk of damage to electronic devices due to impact.

Cushioning and shock absorption: The cushioning properties of Slow Rebound EPDM foam can effectively reduce the impact of vibration and shock on electronic devices. During the transportation or use of electronic devices, this cushioning and shock absorption effect can protect the delicate components inside the device from damage.

Stable support: In addition to impact absorption and cushioning and shock absorption, Slow Rebound EPDM foam can also provide stable support for electronic devices. This support effect can ensure that electronic devices maintain a stable operating state during use and avoid failures caused by vibration or impact.

3. Application cases and effects

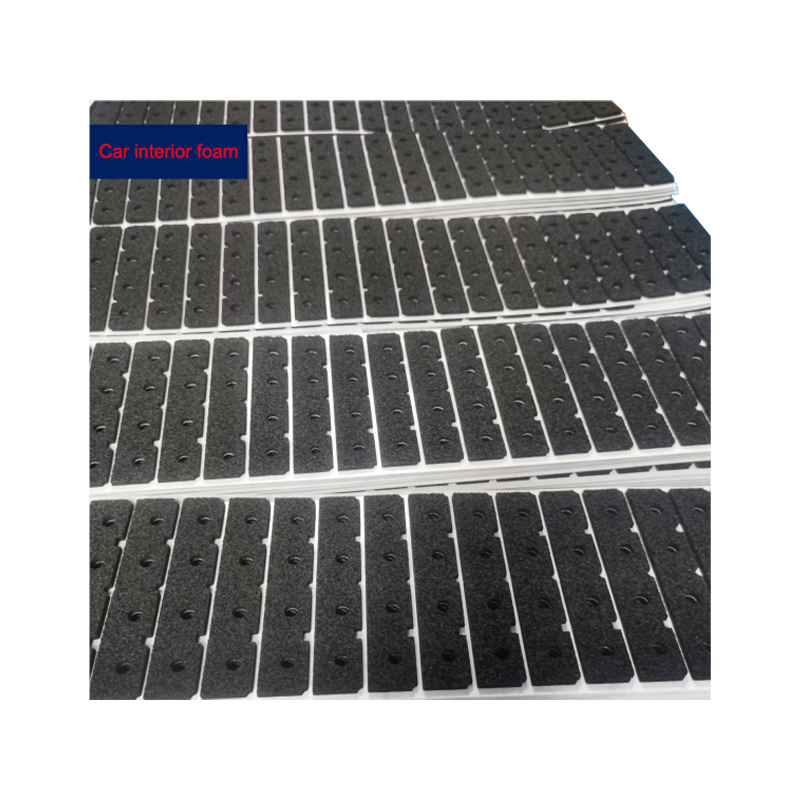

Electronic equipment packaging: Slow Rebound EPDM foam is often used as a filling material for electronic equipment packaging. It can effectively protect electronic equipment from damage due to shock and vibration during transportation.

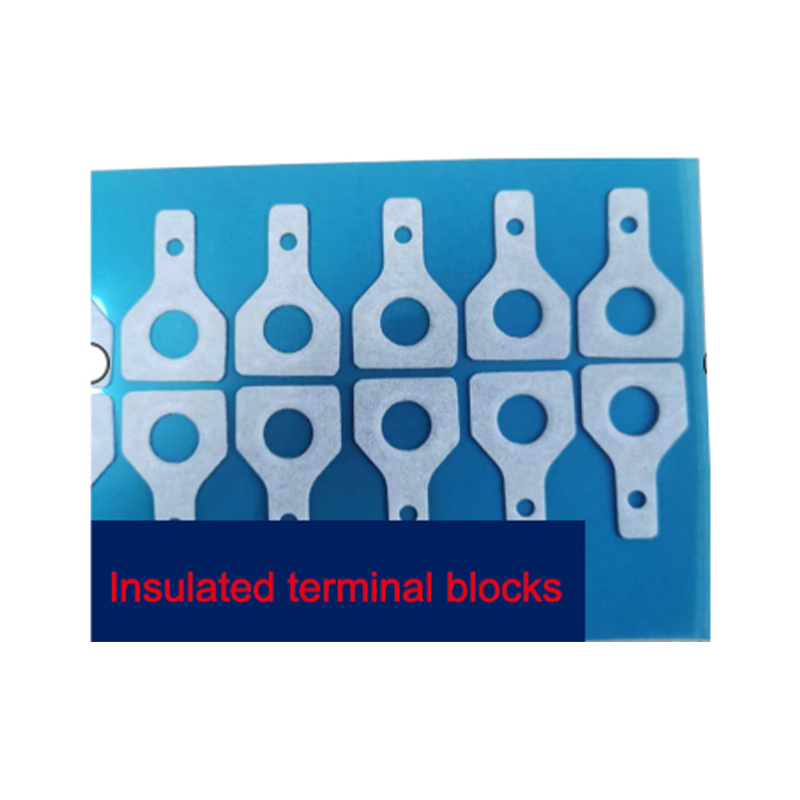

Shockproof pads and buffer layers: Inside electronic devices, Slow Rebound EPDM foam can be used as shockproof pads or buffer layers. These components ensure that the internal structure of electronic devices remains stable and safe when subjected to external impact.

Improve user experience: By providing excellent shock protection, slow rebound EPDM foam can also improve the user experience. When carrying or using electronic devices, users can enjoy the convenience and functions of the device with more confidence.

In summary, slow rebound EPDM foam plays an important role in improving the shock protection of electronic devices due to its unique weather resistance, aging resistance, high and low temperature resistance, slow rebound and cushioning properties. This material can effectively absorb and disperse impact force, reduce the impact of vibration and shock on electronic devices, and provide stable support and protection for electronic devices.

1. Material properties

Weather resistance and aging resistance: EPDM itself has excellent weather resistance and aging resistance, which means that it can be used for a long time in various harsh environmental conditions without easy degradation. This performance is crucial for electronic devices, because electronic devices usually need to operate in various environments, including high temperature, low temperature, humidity, etc.

High and low temperature resistance: EPDM can be used in the range of -40~+120℃ and has the characteristics of high and low temperature resistance. The stability within this temperature range ensures that electronic devices can be well protected under different temperature conditions.

Slow rebound and cushioning: Slow rebound EPDM foam has excellent slow rebound elasticity and can quickly recover its shape when impacted. This cushioning property can effectively absorb and disperse the impact force, thereby protecting electronic devices from damage.

2. Shockproof protection mechanism

Impact absorption: When an electronic device is impacted, Slow Rebound EPDM foam can quickly absorb the impact force and disperse it throughout the material structure. This impact absorption mechanism significantly reduces the risk of damage to electronic devices due to impact.

Cushioning and shock absorption: The cushioning properties of Slow Rebound EPDM foam can effectively reduce the impact of vibration and shock on electronic devices. During the transportation or use of electronic devices, this cushioning and shock absorption effect can protect the delicate components inside the device from damage.

Stable support: In addition to impact absorption and cushioning and shock absorption, Slow Rebound EPDM foam can also provide stable support for electronic devices. This support effect can ensure that electronic devices maintain a stable operating state during use and avoid failures caused by vibration or impact.

3. Application cases and effects

Electronic equipment packaging: Slow Rebound EPDM foam is often used as a filling material for electronic equipment packaging. It can effectively protect electronic equipment from damage due to shock and vibration during transportation.

Shockproof pads and buffer layers: Inside electronic devices, Slow Rebound EPDM foam can be used as shockproof pads or buffer layers. These components ensure that the internal structure of electronic devices remains stable and safe when subjected to external impact.

Improve user experience: By providing excellent shock protection, slow rebound EPDM foam can also improve the user experience. When carrying or using electronic devices, users can enjoy the convenience and functions of the device with more confidence.

In summary, slow rebound EPDM foam plays an important role in improving the shock protection of electronic devices due to its unique weather resistance, aging resistance, high and low temperature resistance, slow rebound and cushioning properties. This material can effectively absorb and disperse impact force, reduce the impact of vibration and shock on electronic devices, and provide stable support and protection for electronic devices.